Building better with less

We are scaling low-carbon construction using innovative brands such as ECOPact low-carbon concrete and ECOPlanet low-carbon cement. Our smart design systems, such as 3D concrete printing with TectorPrint or prefabricated solutions, can reduce material use by up to 50%.

LOW-CARBON BUILDING

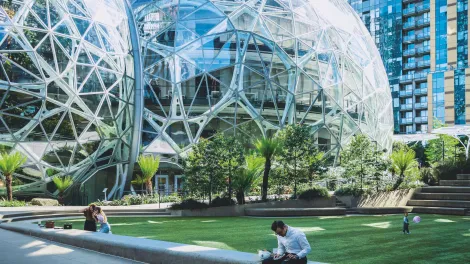

WE ARE MAKING SUSTAINABLE CONSTRUCTION POSSIBLE AT SCALE AROUND THE WORLD – FROM ZURICH TO NEW YORK AND MEXICO TO MANILA – WITH OUR INNOVATIVE AND SUSTAINABLE BUILDING SOLUTIONS.

With our world’s rising population and increased urbanization, Holcim is building better with less to improve living standards for all.

Since concrete is infinitely recyclable, versatile and resilient, we are continually innovating to make low-carbon concrete the building material for a net-zero future. Our ECOPact concrete offers significant CO2 reductions without compromising on performance. When permitted by regulations, ECOPact can include recycled construction demolition materials, further closing the resource loop.

ECOPlanet is the industry’s broadest range of low-carbon cement. We use calcined clay and construction demolition materials in ECOPlanet formulations to reduce buildings’ CO2 footprint by up to 50%. By helping us build better with less, ECOPlanet plays a key role in meeting the needs of population growth and urbanization.

SMART DESIGN

We are empowering smart design to use minimum materials for maximum strength.

We make this possible with our proprietary technologies from our proprietary 3D concrete printing ink TectorPrint, to our ultimate performance concrete, DYNAMax.

DYNAMax, Holcim’s ultimate performance concrete, enables our customers to build better with less. DYNAMax is characterized by high strength, outstanding durability and superior rigidity. By lowering material demand, it also offers a reduced carbon footprint.

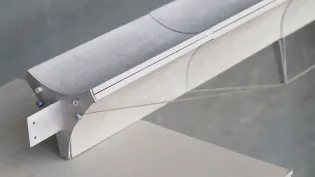

TectorPrint is Holcim’s proprietary 3D concrete printing ink. TectorPrint empowers smart design, using concrete at its best – with a minimal amount of material for maximum strength. Smart design applications like the Rippmann Floor Systems can reduce material use by up to 50% with no compromise in performance.

One of our breakthrough innovations to help the world build better with less is carbon prestressed concrete (CPC). Using high-strength concrete reinforced with prestressed carbon fibers, CPC slabs use a proprietary process and patented technology. This enables the same load-bearing capacity as traditional reinforced concrete slabs, while being up to five times thinner and lighter. In addition to enabling resource-efficient construction systems, the absence of steel means extending its service life up to 100 years. At end of life, CPC systems can be disassembled and reused or fully recycled.

Digitalization

We are optimizing material use and reducing waste through digital solutions.

With urbanization on the rise, digitalizing construction can help deliver structures that can be built faster, last longer and contribute to a more sustainable built environment. We are optimizing material use and reducing waste through digital solutions, from Holcim Digital Concrete Services to ConcreteDirect.

ConcreteDirect is the industry’s leading ready-mix management platform for more efficient, safer and environmentally friendly concrete use at every jobsite. Offering real-time data on truck location and status, e-tickets, delivery and product performance, and EPDs, the platform enables increased transparency and efficiency and reduces waste and material use.

With our suite of digital solutions, we are helping to accelerate smart construction:

• Holcim SMARTCast provides digital monitoring of concrete strength and temperature for on-site optimization.

• Holcim SMARTFlow uses digital simulation to measure concrete flowability and match it to the appropriate pump for use in the field.

• Holcim SMARTherm simulates concrete temperature evolution for mass elements to ensure reliable thermal development without defects.