With population growth and with urbanization on the rise, we have to rethink the way we build cities. Finding ways to decarbonize the construction phase of a building’s lifecycle is critical to reaching the world's climate targets.

As the main ingredient in concrete, cement is an essential building material to accommodate the demand for new buildings. Decarbonizing cement and concrete is therefore critical.

Producing net-zero cement starts with low-carbon formulation, substituting limestone with innovative raw materials such as calcined clay. Using decarbonized energy is another lever for lowering emissions from cement production. For all the remaining carbon dioxide (CO2) emissions after the first two levers have been deployed, carbon capture, utilization and storage (CCUS) plays an essential role.

Harnessing advanced technologies like CCUS is a game-changer to meet long-term climate goals. At Holcim, we are on a mission to decarbonize building, to shape a net-zero future that works for people and the planet. Our advanced CCUS roadmap positions us uniquely as the right partner to scale up net-zero cement around the world.

But what exactly is CCUS, how does it work and how can different CCUS technologies help us reach global climate goals?

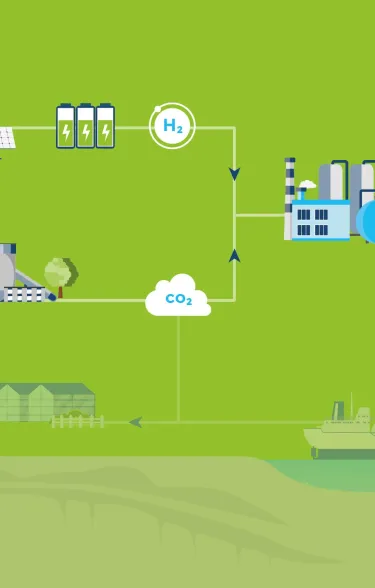

HOW CCUS WORKS

The process involves capturing CO2 emissions before they are released into the atmosphere, and either utilizing the CO2 in various applications or safely storing it.

CCUS allows us to reduce greenhouse gas emissions from hard-to-abate sectors, such as cement, offering a viable pathway towards meeting global climate goals and transitioning to a net-zero economy.

There are several mature carbon capture technologies with the potential to decarbonize cement production:

HOLCIM'S CCUS PATHWAYS

Different CCUS technologies can be deployed in many different places around the world. Options for the capture, transport, utilization and storage of CO2 vary from one site to another, and the regulatory environment differs from one country to another.

At Holcim, our comprehensive, bottom-up approach allows us to tailor pathways and value chains based on local conditions, ensuring cost-effective, viable and scalable solutions.

FOUR PATHWAYS

Our projects span four main storage and utilization pathways.

1. MINERAL CARBONATION

Mineral carbonation, also known as CO2 mineralization, is a form of utilization through which CO2 is reacted with minerals to form carbonates, storing the CO2 permanently. In the cement sector, this reaction provides a way of using captured CO2 as part of a raw material to produce new building materials.

2. CONVERSION UTILIZATION

We are exploring new pathways to use CO2 in the production of fuels, chemicals and plastics. CO2 can be repurposed by reaction with green hydrogen to produce fuels that can decarbonize the aviation and maritime sectors, or can be used to produce chemicals and plastics.

3. MERCHANT MARKET UTILIZATION

Captured CO2 can be used for greenhouse plants as a crop growth enhancer or in the food and beverages industries, for example for beverage carbonation.

4. STORAGE

CCUS technologies capture CO2 from a facility. It is then transported to a location where it can be safely stored underground in deep geological formations. CO2 can be transported by pipeline, train, ship or truck, for storage in depleted oil and gas reservoirs, or saline aquifers.

OUR CCUS ROADMAP

We are scoping CCUS and mineralization projects around the world based on mature technologies, robust partnerships and value chains. As of November 2025, Holcim has eight CCUS projects supported by the EU Innovation Fund. Collectively, these projects will allow us to supply our customers with over 8 million tons of near-zero cement by 2030.

EXPLORE SOME OF OUR CCUS PROJECTS AROUND THE WORLD

Lägerdorf, Germany

The Carbon2Business project aims to capture CO2 from our plant at Lägerdorf and repurpose it as an industrial raw material, together with partners thyssenkrupp Industrial Solutions AG and Linde Engineering. Using a Carbon Processing Unit and a first-of-its-kind implementation of oxyfuel technology, the project sets a new standard in low-carbon cement production and industrial climate innovation.

Pathway: conversion utilization

Annual CO2 capture: around 1.2 million tons

Operational by: 2028-2029

Block Media

Kujawy, Poland

The GO4ECOPlanet project will take flue gas from our cement plant in Kujawy and process it in a CO2 capture plant which produces 99.9% pure CO2 using Air Liquide’s Cryocap™ FG technology. The installation will capture 100% of CO2 emissions from clinker production and the CO2 will be transported to and stored in depleted oil and gas fields.

Pathway: storage

Annual CO2 capture: around 1.2 million tons

Operational by: 2027

Block Media

Koromačno, Croatia

KOdeCO net zero aims to create a CCS chain from Holcim's Koromačno cement plant to the first permanent offshore storage in the Mediterranean Sea, which is essential to transform industry in the south of Europe. The project is a large-scale industrial demonstration of disruptive "Cryocap" technology that at plant level will bring 20% electricity savings, higher efficiency, circularity of condensate and reduced water consumption, while using 90% renewable electricity.

Pathway: storage

Annual CO2 capture: around 366,000 tons

Operational by: 2028

Block Media

Le Teil, France

A partnership with Elyse Energy, the eM-Rhône project will produce e-methanol using renewable hydrogen production and CO2 captured from our plant in Le Teil. E-methanol is a valuable platform molecule for various chemical projects and a low-carbon alternative fuel. The project will establish the first large-scale e-methanol plant in France, which will produce 138kt every year.

Pathway: conversion utilization

Annual CO2 capture: 195,000 tons

Operational by: 2028

Obourg, Belgium

In Belgium, the GO4ZERO project will deploy an innovative air-oxygen switchable kiln with carbon purification technology at Holcim's cement plant in Obourg. It will ship the purified CO2 via the Fluxys network for sequestration under the North Sea.

Pathway: storage

Annual CO2 capture: around 1.1 million tons

Operational by: 2029

Block Media

Milaki, Greece

The OLYMPUS project will be an important part of Holcim’s European decarbonization roadmap, while enabling the development of storage capacity in southern Europe. Here we are developing a new scalable and replicable technology (“OxyCalciner & CryoCap Oxy” combination), allowing low capture variable cost, and transforming the plant into a net carbon removal site by implementing this highly innovative technology combination.

Pathway: storage

Annual CO2 capture: around 1 million tons

Operational by: 2027

Block Media

Carboneras, Spain

The Lighthouse project, in collaboration with Carbon Clean and Sistemas de Calor, will capture CO2 from flue gas at Holcim’s Carboneras plant and use it agriculturally to accelerate crop production. This will increase farm efficiency by reducing the water and soil consumption ratio per kg of vegetable production.

The H2DECARBANOL project, together with partners GALP and ENEL, will capture and partially use the CO2 for e-methanol, and the remaining CO2 will be stored.

Pathway: merchant market and conversion utilization, storage

Annual CO2 capture: around 0.9 million tons

Operational by: 2028-2029

Saint-Pierre-La-Cour, France

The Capt4Climate project is an important project not only for Holcim, but also for France’s decarbonization roadmap, which aims to halve industrial CO2 emissions by 2030. Holcim is implementing new, scalable carbon capture technology in its Saint-Pierre-la-Cour plant. It will also promote the development of efficient infrastructure for the transport to and pre-storage of the CO2 at Saint Nazaire port together with partners Elengy and GRTGaz, specialists in gas handling and gas terminaling.

Pathway: storage

Annual CO2 capture: around 1 million tons

Operational by: 2030

Mannersdorf, Austria

At first capturing and storing CO2, the ultimate aim of the Carbon2Product Austria project is to create a cross-sectorial value chain, which will use the captured CO2 as a resource. In combination with green hydrogen provided by VERBUND, the captured CO2 could be transformed by OMV into renewable-based hydrocarbons, a feedstock for Borealis to manufacture value-add plastics.

Pathway: conversion utilization

Annual CO2 capture: around 0.75 million tons

Operational by: 2030

SCALING UP CCUS

To establish CCUS as a long-term solution to meet climate targets, collaboration is essential. And this starts with sorting fact from fiction to unlock the business case for CCUS.

Collaboration across the value chain

The momentum for the deployment of CCUS has grown substantially in recent years, with around 300 projects in various stages of development across the CCUS value chain in different industries.

We understand that when it comes to accelerating the adoption of CCUS, we cannot do it alone. We need deep collaboration and strong partnerships between public authorities, private companies, local stakeholders and other value chain partners to secure the development of technologies. That is why we are working in close collaboration with our partners across our portfolio of projects.

“Working with other multinationals as well as start-ups, our objective is to create a portfolio of diverse and cost-effective solutions that can be scaled up across the company to advance our decarbonization journey, with the aim of having more than 5 million tons per year of CO2 capture capacity in operation by 2030.”

Talk to an expert

Want to learn more about our CCUS projects? Drop us a line, and someone from our team will be in touch.