SUSTAINABILITY DRIVING PROFITABLE GROWTH

We’ve built our sustainability plan around four focus areas to strengthen Holcim’s leadership in sustainable construction.

1.SCALING OUR SUSTAINABLE OFFERING

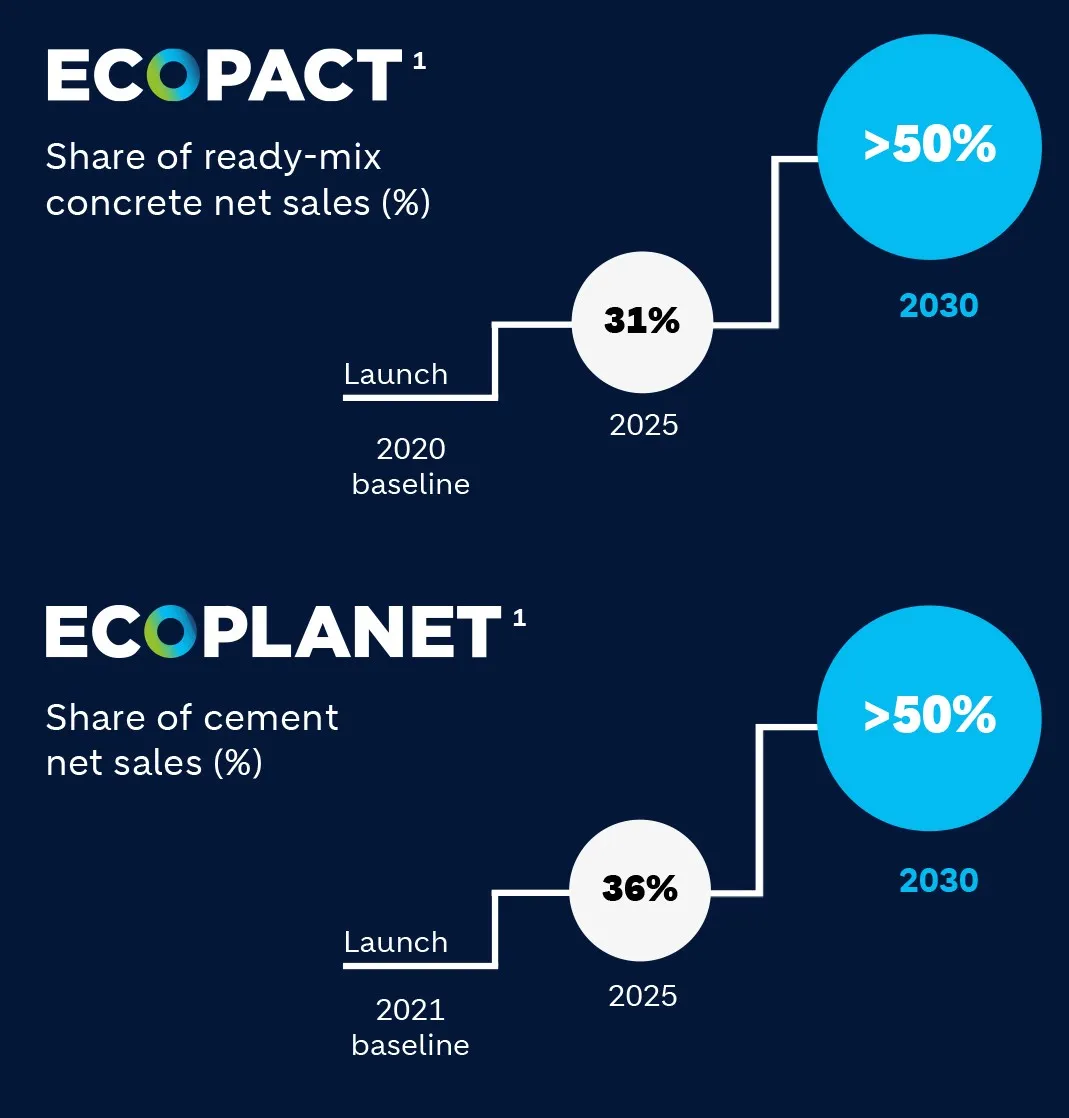

We’re scaling our sustainable offering, including ECOPact and ECOPlanet, to meet our customers’ most ambitious goals.

Holcim has a 2030 target to reach over 50% of net sales from ECOPact in ready-mix concrete, and over 50% of net sales from ECOPlanet in cement.

In 2025, ECOPact had a 31% share of ready-mix concrete net sales (+5 pp versus 2024) while ECOPlanet had a 36% share of cement net sales (+2 pp versus 2024).

Our sustainable offering is tailored to customer demand and powered by premium brands that are circular, low-carbon, resilient, energy-efficient, and smart.

Read how ECOPact is helping build Europe’s largest urban regeneration project, The Ellinikon in Athens, Greece.

Note: All baselines are restated for discontinued operations.

1ECOPact and ECOPlanet offers 30% lower CO2 emissions compared to ordinary (CEM I/OPC) concrete and cement.

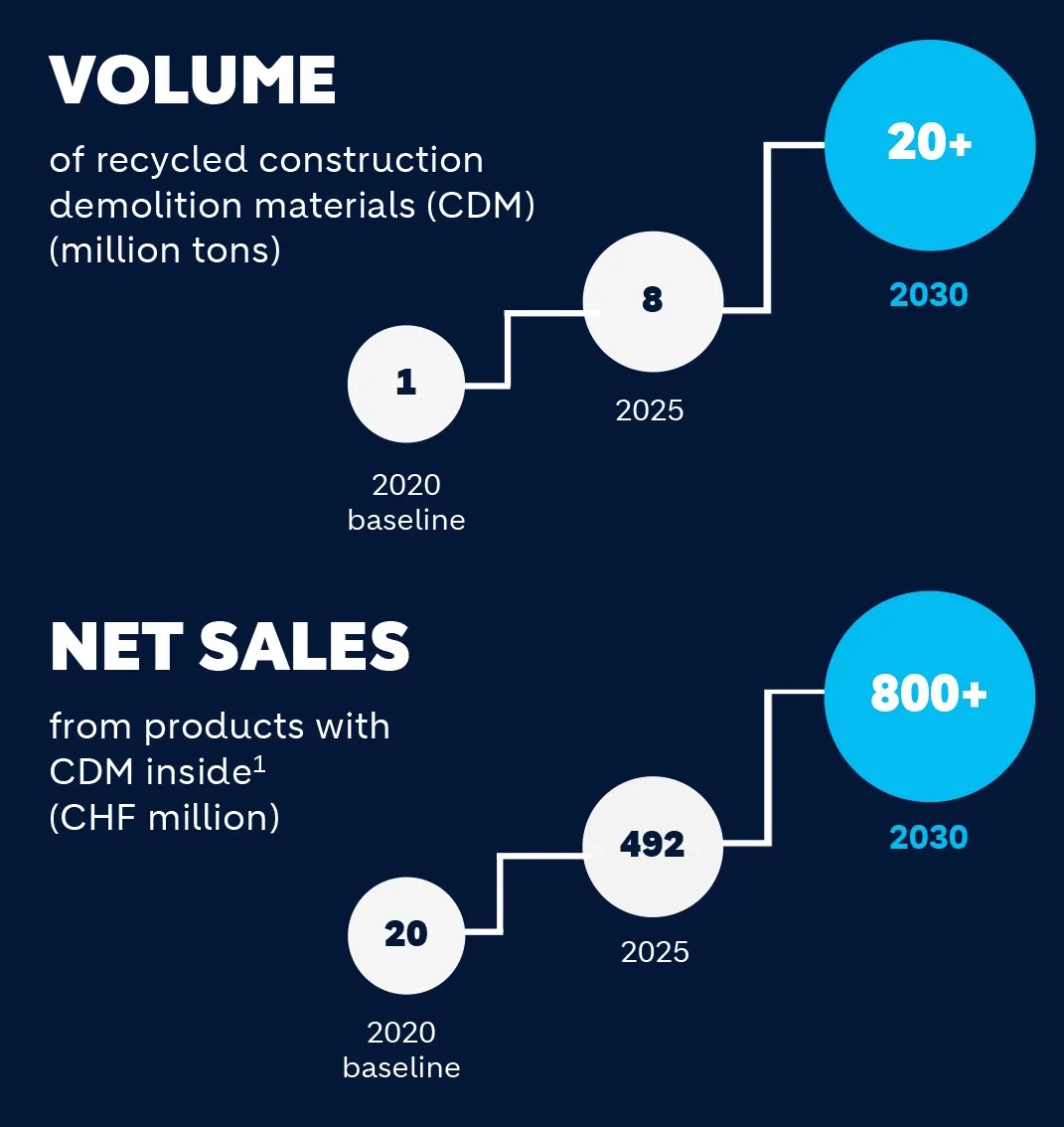

Note: All 2020 baselines have been restated for discontinued operations.

1Defined as products and solutions with ECOCycle inside containing at least 10% construction demolition materials.

2. ADVANCING CIRCULAR CONSTRUCTION

Holcim is accelerating profitable growth in circular construction by increasing our construction demolition materials (CDM) volumes using our ECOCycle technology.

In 2025, we recycled more than 8 million tons of CDM (+23% versus 2024), and are targeting more than 20 million tons by 2030.

Scaling this technology in metropolitan areas, we can build cities from cities, creating high-value solutions that save valuable primary raw materials, minimize waste, and drive profitable growth.

Discover Recygénie the world’s first 100% recycled concrete building with ECOCycle inside.

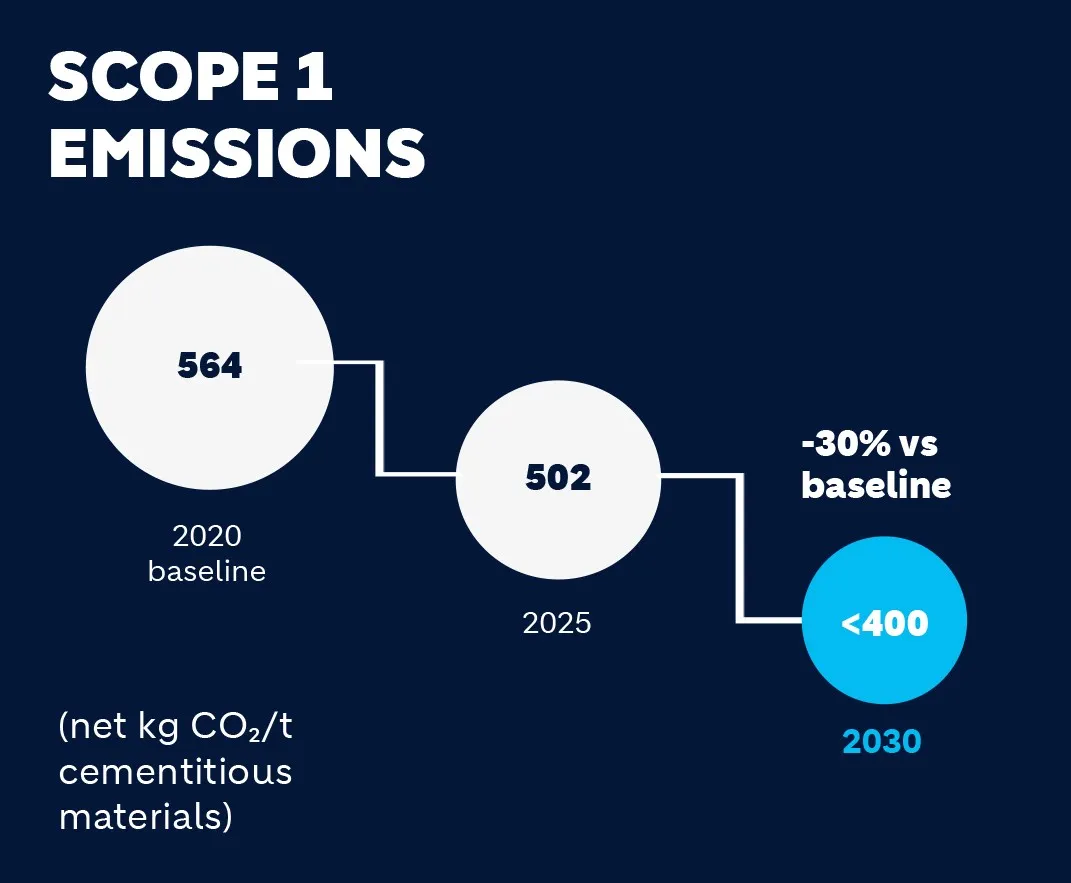

3. INNOVATION ACCELERATING DECARBONIZING

Innovation is accelerating decarbonization for Holcim, and we aim to reduce Scope 1 emissions to below 400 kg CO2 net per ton of cementitious materials by 2030.

To achieve this, we’re focusing on three levers:

- Formulation: Developing cement and concrete mixtures with a lower clinker content and increasing the use of alternative raw materials and binders.

- Energy: Increasing the use of alternative fuels through our Geocycle business, investing in renewable energy sources and improving energy efficiency in our operations.

- Advanced technologies: Pioneering and scaling advanced technologies, with a focus on carbon capture.

In 2025, we reduced our Scope 1 emissions by 11% to 502 kg CO2 net per ton of cementitious materials versus a restated 2020 baseline.*

Learn how innovation is accelerating decarbonization for Holcim.

Note: 2020 baseline has been restated for discontinued operations and other material changes in scope.

Note: 2020 baseline has been restated for discontinued operations and other material changes in scope.

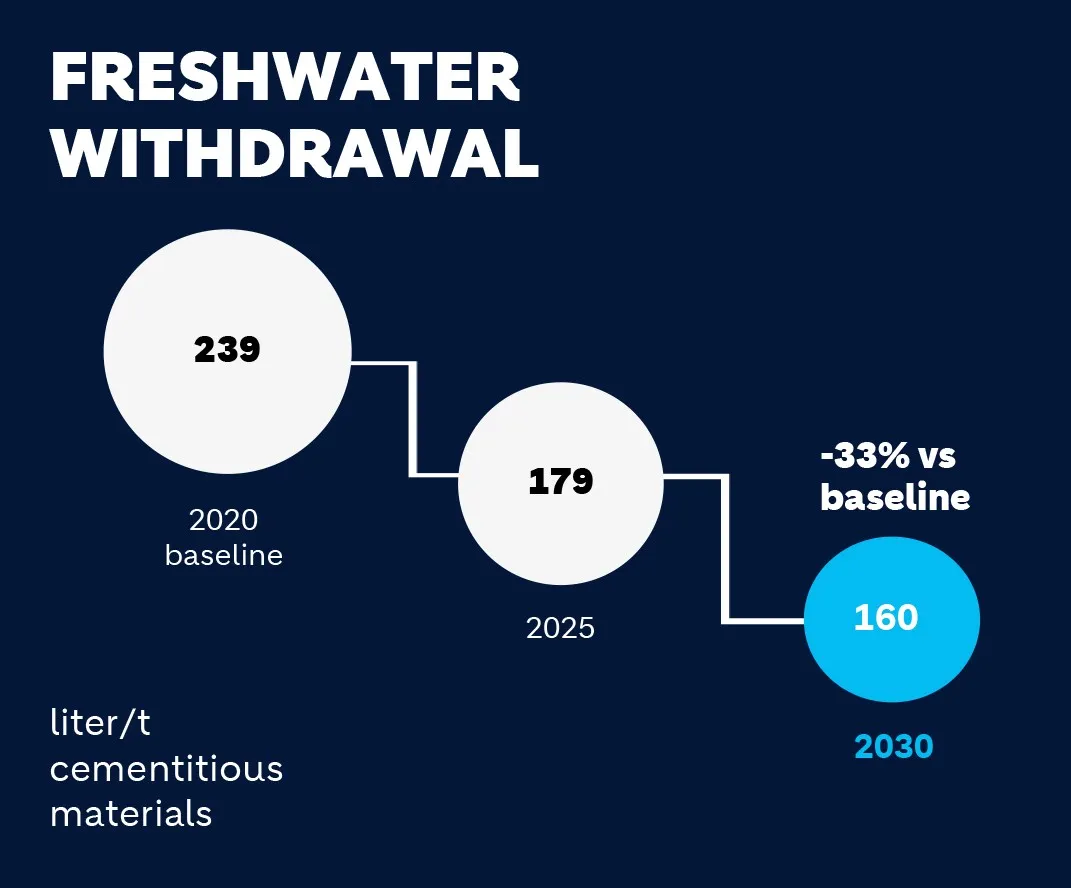

4. BUILDING A NATURE-POSITIVE FUTURE

Holcim is building a nature-positive future by bringing nature into cities, while reducing freshwater withdrawal by 33% in our operations by 2030 versus a 2020 baseline:

- Water: Setting the industry’s most ambitious science-based freshwater reduction targets.

- Biodiversity: Transformative rehabilitation measured by a science-based methodology developed with the International Union for Conservation of Nature (IUCN).

- Nature-positive solutions: Offering a wide range of solutions that bring nature into cities.

In 2025, we reduced our freshwater withdrawal by 25% to 179 liter/t of cementitious materials, versus a restated 2020 baseline.*

Holcim is targeting a freshwater withdrawal of 160 liter/t of cementitious materials by 2030.

Discover Holcim’s pioneering science-based freshwater targets

*All restated baselines and 2024 figures are restated for discontinued operations and other material changes in scope.