Our net-zero journey

Our industry-leading net-zero pledge includes Scope 1, 2 and 3 targets, validated by the Science Based Targets initiative (SBTi). Addressing both direct and indirect impacts, these objectives will guide our net-zero strategy for decades to come.

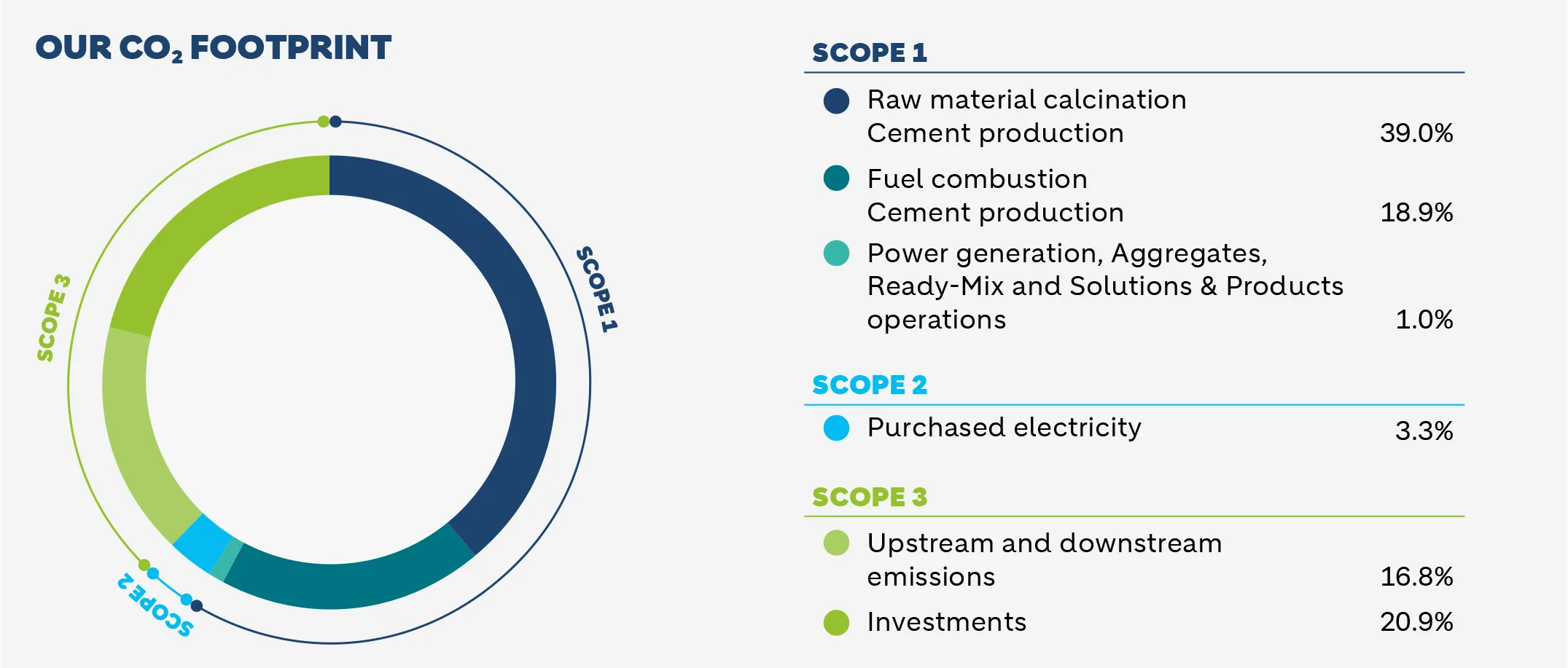

Our CO2 footprinT

Scope 1 emissions – released directly from our operations – account for 58.9% of our footprint and are at the core of our emissions reduction strategy. Most of these emissions come from cement production. 39.0% are generated by the raw materials we use to produce clinker. Fuel consumption used to heat cement kilns is another significant source of emissions. A small share of Scope 1 emissions come from operations linked to Solutions & Products, aggregates and ready-mix concrete.

Scope 2 emissions account for 3.3% of our carbon footprint. These include indirect emissions from the generation of purchased electricity consumed by our owned or controlled equipment.

Scope 3 emissions account for 37.7% of our carbon footprint. These include all other indirect emissions generated across our value chain, such as for transportation and the extraction and production of purchased materials and fuels. Scope 3 also includes direct emissions from non-consolidated companies and investments.

OUR PATHWAY TO NET ZERO

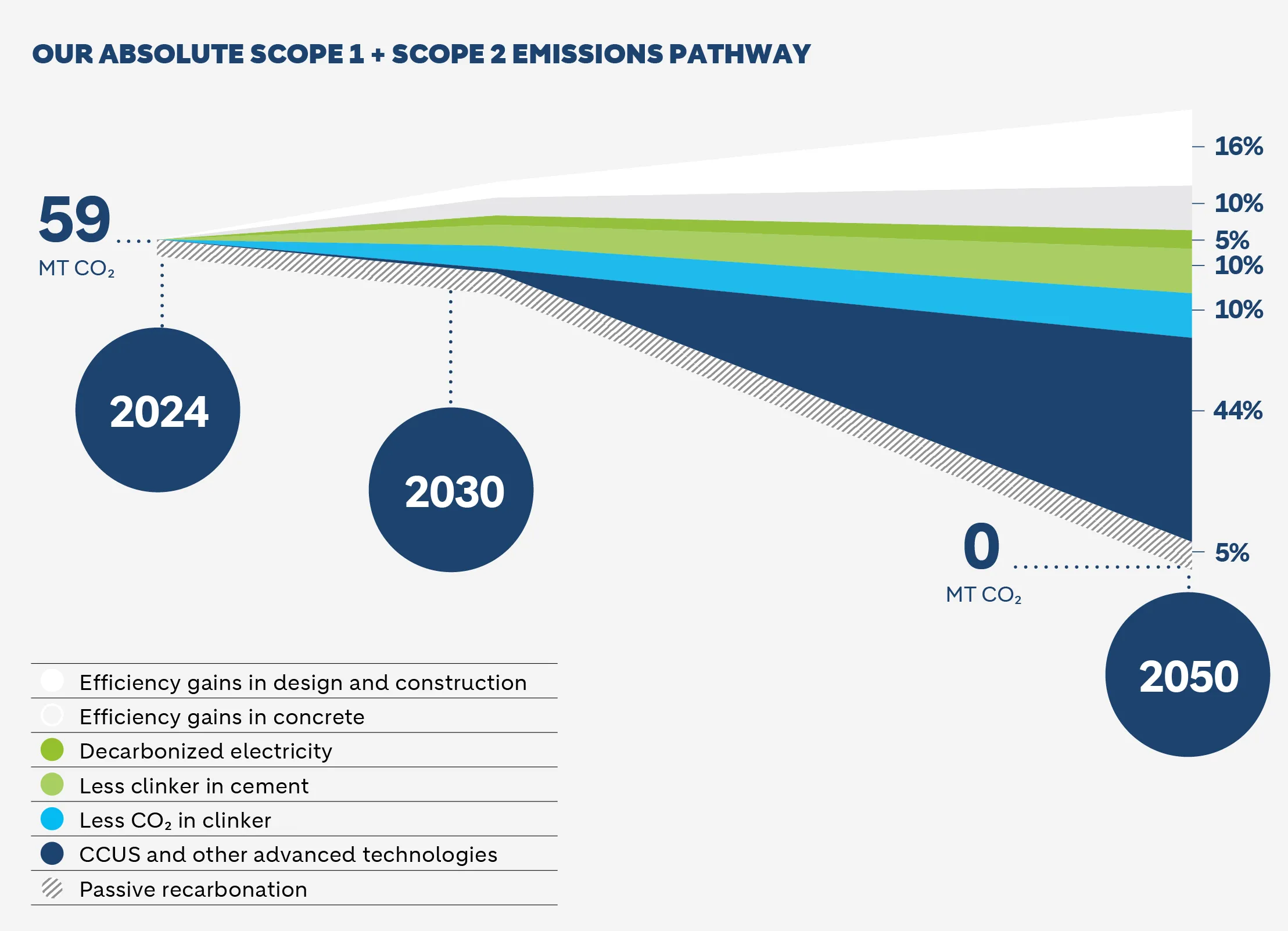

Our pathway to 2030 is clear. To reach our Scope 1 and Scope 2 commitments, we will reduce our clinker factor, use alternative fuels and raw materials, and increase our use of renewable energy.

We are scaling up advanced technologies such as carbon capture, utilization and storage (CCUS), which will make an increased contribution in terms of reaching our targets post-2030.

We aim to produce 8 million tons of near-zero cement each year from 2030. To meet this target, we have identified 17 flagship projects based on mature technologies and robust partnerships and value chains.

Our reduction ambitions

Holcim is committed to taking the following strategic actions to achieve net zero in our Scope 1 emissions:

ALTERNATIVE RAW MATERIALS

Substituting waste materials and by-products from other industries as raw materials in the production process.

CLINKER FACTOR

Reducing the level of CO2 in clinker as well as the clinker factor of our cement. Beyond recycling clinker, replacing it in our final cement products with mineral components significantly reduces the carbon intensity of the cement product.

ENERGY EFFICIENCY

Modernizing kilns to lower CO2 levels and using digital solutions to create connected, smart and energy-efficient sites that will complement our other decarbonization levers.

ALTERNATIVE FUELS

We are transforming non-recyclable waste into high biogenic carbon fuels to replace traditional fossil fuels, as well as increasing the biomass content in the fuels we use.

CCUS AND OTHER TECHNOLOGIES

Accelerating large-scale carbon capture, utilization and storage solutions in partnership with leaders in various sectors.

On top of the decarbonization of the electrical grid, a range of factors are involved in reducing our Scope 2 emissions to net zero:

WASTE HEAT RECOVERY

Repurposing excess heat from cement kilns to generate electricity, with plans to significantly increase the number of waste heat recovery units we own by 2030.

SOLAR, HYDRO- AND WIND POWER

Maximizing the use of renewable energy in our plants, including through onsite renewable power generation. In Belgium, we plan to operate our first floating photovoltaic installation from 2025 to supply up to 15% of our Obourg plant’s electricity.

POWER PURCHASE AGREEMENTS

Continuing to expand our renewable energy portfolio by collaborating with power producers. In Europe, we secured additional long-term supply from renewable sources in Greece, Spain, Belgium and Austria. We also entered into a power purchase agreement (PPA) in the Philippines to supply geothermal power starting in Q3 2024 and began installation of several rooftop solar projects.

With our Scope 3 intermediate targets validated by SBTi, we are prioritizing the following actions to reduce emissions in this category:

FUELS AND ENERGY

Replacing traditional fossil fuels with locally sourced, alternative and non-extractive fuels.

DOWNSTREAM TRANSPORTATION

Moving volumes from road to waterways or rail transportation, and deploying fleets powered by electricity and more eco-friendly fuels.

PURCHASED CLINKER AND CEMENT

Requiring our clinker and cement suppliers to provide the CO2 information related to their products through Environmental Product Declarations (EPDs).

OTHER PRODUCTS AND SERVICES

Including CO2 requirements in the tendering process and integrating CO2 as a parameter in our “Total Cost of Ownership” models used to drive purchasing decisions.