Holcim’s new wave in marine

ecosystem restoration

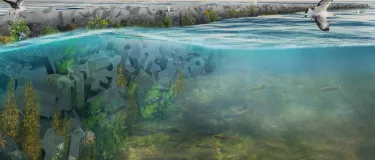

At Friedrichsort pier near the city of Kiel, Germany, fish are checking into special “hotels” enabled by Holcim’s advanced 3D printing technology. These form part of a new artificial reef we’ve donated and installed to boost marine biodiversity and mark the Ocean Race Europe 2025 start.

Covering approximately 24m2 of seabed, the reef was installed in June 2025 and integrates a range of Holcim’s innovative coastal protection solutions. The 3D-printed fish hotels sit alongside 400 CO2-reduced Xstone blocks that make up the reef, some of which are made using bioactive concrete and biochar – to restore and boost the marine ecosystem in Kiel Bight.

Holcim is driven by a clear purpose to build progress for people and the planet, with sustainability driving profitable growth through our NextGen Growth 2030 strategy and the desire to build a nature-positive future by bringing nature and biodiversity into cities.

Demand is growing for sustainable and resilient construction, and the artificial reef is part of a wider transformation in Kiel Bight, as Jens Ewert, Project Manager at Holcim Germany, explains.

3D concrete-printed 24m2 artificial reef donated and installed in Friedrichsort

400 Xstone blocks for coastal resilience and biodiversity restoration – including several net-zero biochar blocks

Specially designed “fish hotels” offer shelter and breeding spaces for local species

Transforming Kiel Bight

“Until recently, the area at the Friedrichsort pier was a barren post-war marine munition dumpsite, with little marine life,” Jens says. “Thankfully, local authorities recently cleaned away the ammunition and launched a project to create a new pedestrian pier.”

Team Holcim-PRB’s skipper Nicolas Lunven promised to donate an artificial reef as part of his solo round-the-world Vendée Globe race. When it was time to decide where the reef should be installed, Kiel was the obvious choice, as the starting point of the Ocean Race Europe 2025.

Jens and his team approached the local authorities to ask whether they could donate the artificial reef and the answer was a resounding “Yes!”

So we got to work to donate not just any artificial reef, but one that truly showcases our commitment to innovation, sustainability and building a nature-positive future with solutions that help biodiversity thrive.

Innovation for marine revitalization

The reef will revitalize the local marine ecosystem using Holcim’s innovative marine solutions: CO2-reduced Xstones with bioactive concrete elements, net-zero Xstones that also incorporate biochar, and 3D-printed fish hotels.

Bioactive concrete has a surface texture and mineral composition that is designed to stimulate natural colonization by a great diversity of local marine animals and plants. This enhances marine biodiversity and supports ecosystem regeneration, transforming hard infrastructure into living reefs.

Used to make the Xstones, these materials promote algae growth and provide critical habitat for small marine life and fish species such as cod, with the specially developed and 3D-printed “fish hotels” offering additional shelter and breeding spaces.

What are Xstones?

Xstone is a coastal armor block that strengthens coastal defense systems such as rivergroynes, banks, offshore wind farms and many other applications. Xstone can significantly decrease material use for an equal structure: its shape and high porosity allows us to build more with less material.

At the Holcim Innovation Center, our biologists are developing advanced methods to improve the ecological value of the bioactive concrete used in Xstone blocks, making them a protective structure against waves and rising water levels, and a natural reef that supports algae and other basic organisms in the food chain. The shape of Xstone creates natural habitats, with internal corridors and sheltered zones where flora and fauna can develop, to help restore biodiversity in marine environments.

“We use ECOPlanet low-carbon cement and recycled aggregates in Xstone production, making it a sustainable building solution for coastal infrastructure. But we didn’t want to stop there,” says Tom van Rijswijk, sustainability advisor for product development at Holcim Coastal.

That’s why his team decided to do something truly pioneering – pilot our innovative biochar technology for the first time in Xstone production.

Pioneering use of biochar

“We created the first ever net-zero* Xstone – a pioneering coastal protection block that combines biochar and bioactive concrete to tackle both climate change and biodiversity loss. By integrating biochar, a carbon-rich material made from organic waste, we permanently sequester CO2 – up to 3 tons per ton of biochar – making the Xstone net-zero*,” Tom explains.

The artificial reef donated and immersed in the Friedrichsort harbor contains 400 low-carbon and several pilot net-zero* Xstone blocks.

“The net-zero* Xstone is a huge source of pride for my team because it’s a milestone in sustainable marine engineering – combining coastal resilience, carbon removal, and ecological regeneration in one modular solution. It’s how we’re building nature-positive infrastructure for a net-zero future.”

*scope of concrete production phases (A1-A3 cradle to gate) in Life Cycle Assessment. Assumes average transportation distance of 175km for cement and filler & 165km for aggregates.

Model collaboration brings reef to life

For Kiel's Environmental Officer, Alke Voss, the artificial reef at the Friedrichsort pier is “a godsend for marine conservation” that promotes biodiversity and the natural protection of the marine environment.

“Such innovative projects demonstrate how sustainable coastal protection and nature conservation can go hand in hand. This is an important step for the preservation of our marine habitats," Alke says.

With a multi-year monitoring program in place, the aim is to gain valuable insights for marine conservation by comparing the performance of the different materials.

"By constructing this artificial reef using our Xstones, we’re expanding marine habitats while simultaneously strengthening coastal protection. Kiel is the ideal location, and we want to thank everyone involved for the smooth implementation of this project, and Kiel Civil Engineering Office in particular," Jens concludes.