The heartbeat of Holcim is climate action

ANTONIO CARRILLO

Vice President of Sustainability

Every day my team and I wake up with a profound sense of purpose – to build progress for people and the planet. This is Holcim’s heartbeat as we deliver on our industry-leading sustainability roadmap to achieve net zero by 2050. Let’s see how we’re taking climate action.

2.5 billion more of us are expected to live in cities by 2050. Clearly we need to build, but we need to do so as sustainably as possible. At Holcim we’re doing so as the leading partner for sustainable construction, and this sustainability is driving profitable growth.

Holcim is a climate leader in our industry. We were among the first companies worldwide to have our 2030 and 2050 CO2 reduction targets validated by the Science Based Targets initiative (SBTi). I remember the pride I felt, but also the responsibility, when we announced this.

We’ve already made strong progress towards our 2030 targets, which are aligned with the SBTi’s revised 1.5°C framework. And we’ve set the target of reducing our net emissions below 400 kg CO2 net / t of cementitious by 2030, as part of our NextGen Growth 2030 strategy.

To achieve our net-zero targets let’s look at the three decarbonization levers that Holcim’s teams are focused on: developing innovative low-carbon formulations, shifting to lower-carbon energy sources and deploying carbon capture utilization and storage (CCUS).

Innovative formulation

With formulation, we’re making great strides with the use of alternative raw materials and mineral components. One of our main focus areas is scaling the use of a calcined clay, which is obtained through the calcination of natural clays at a relatively low temperature.

This is a significant shift in our industry. By replacing limestone-based clinker with calcined clay we can produce cement with up to 50% less CO2 than standard cement. We now produce 10 calcined-clay based cements at eight plants worldwide, and we’re expanding production further.

Let’s travel to Venice for another example. At the 2025 Architecture Biennale we showcased the world’s first application of a breakthrough biochar technology that turns buildings into carbon sinks, built with a net-zero biochar concrete with 100% recycled aggregates inside.

It was amazing to see our Basic Services Unit housing prototype in real life and to share our story with the world. Technologies like this have immense potential to decarbonize building, and I’m genuinely excited to see the results of biochar pilots we’re running across our markets.

Of course, all this innovation is customer-centric, driving value creation and enabling us to scale our sustainable offering. The numbers prove it. In Q3 2025, low-carbon ECOPact grew to account for 31% of ready-mix net sales, low-carbon ECOPlanet 35% of cement net sales.

Lower-carbon energy

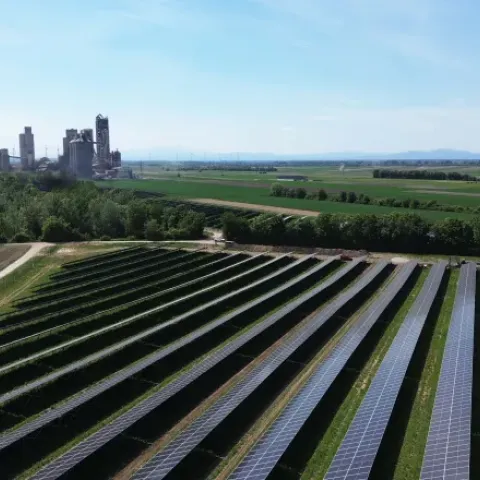

Holcim is shifting to lower-carbon energy across our value chain – from alternative fuels and renewable electricity to waste-heat recovery systems. By 2030, we will increase our fossil fuel replacement rate by 50%, up from 35% currently.

How will we do this? By closing material loops and reducing the carbon footprint of the clinker manufacturing process. Here Holcim’s Geocycle business works to transform non-recyclable waste into high biogenic carbon fuels that replace traditional fossil fuels in our kilns.

When it comes to renewable energy we have many good examples, here’s just one. In Colombia, we’ve already reached 100% renewable energy to run our operations, supplied from hydroelectric and solar plants, paving the way for other countries to follow.

Carbon capture, utilization and storage (CCUS)

Carbon capture, utilization and storage (CCUS) is another key decarbonization lever, which involves using proven carbon capture technologies to separate CO2 from flue gases, which can then be compressed for permanent safe storage or utilization.

Holcim now has eight large-scale EU-supported CCUS projects, the largest number of in our industry to date. These will enable us to offer 8 million tons of near-zero cement to our customers from 2030 while supporting the European Union’s Clean Industrial Deal.

Our Carbon Hub CPT 01 project in Campulung in Romania is the latest to be selected for a grant. This support for Eastern Europe’s first full-scale onshore CCS project is a testament to the strength of our engineering teams - as an engineer myself, kudos - as well as the maturity of our technologies and advanced partnerships spanning the value chain.

Let’s partner for progress

These partnerships really matter. Because as the leading partner for sustainable construction, Holcim can’t act alone. To achieve our net-zero targets, we need to collaborate with our customers, suppliers, public authorities and other actors across the construction value chain.

For example, with CCUS we’re playing our part in building industrial carbon management value chains from the ground up. This requires close collaboration with governments and other industrial partners to de-risk novel technologies, and create de-risking tools for carbon management through public policy and institutional mechanisms.

Nature is the new climate

Of course, nature is our climate’s biggest ally, absorbing half of global carbon emissions every year. The business case for integrated action on climate and nature has never been clearer, and I’m delighted to see global events such as COP30 putting nature at the heart of climate action.

This is why nature is central to our industry-shaping sustainability roadmap as part of our 2030 strategy, which builds on our strong foundations of nature action. I invite you to read my colleague Renata Pollini’s excellent blog to learn about “The Nature of our Work at Holcim”.

As recently as 10 years ago no one could have foreseen the technological advances we have now made – from formulation and energy to CCUS and more – that are enabling Holcim to transform the way the world builds, working closely with our partners.

Let’s partner for progress on climate to achieve net zero and build a more sustainable future.