Scaling our sustainable offering with a new state-of-the-art facility in Tilbury, UK

Set in a prime location east of London on the River Thames, our state-of-the-art new Tilbury Cement Works will meet rising demand for innovative, high-performance and sustainable building solutions to build major UK infrastructure projects from 2027.

On this nine-acre site in Tilbury we’re transforming how building materials are processed and delivered, in line with our vision to be the leading partner for sustainable construction as part of our NextGenGrowth 2030 strategy.

With a focus on innovation, agility and environmental responsibility, the facility will serve as a state-of-the-art grinding station and sustainable construction hub for Holcim UK’s lower-carbon and circular product ranges.

Tilbury will be a flagship grinding station and import terminal not only for Holcim but for the wider industry—showcasing how cement manufacturing can evolve to meet the challenges of the construction sector and supply chain resilience.

Tilbury will introduce Holcim’s ECOCycle® circular technology for cement to the UK market

Over 25,000 m3 of concrete from the original site was recycled and reused to build the terminal

Tilbury will meet the region's rising demand for high-performance, sustainable materials

Reliability of supply

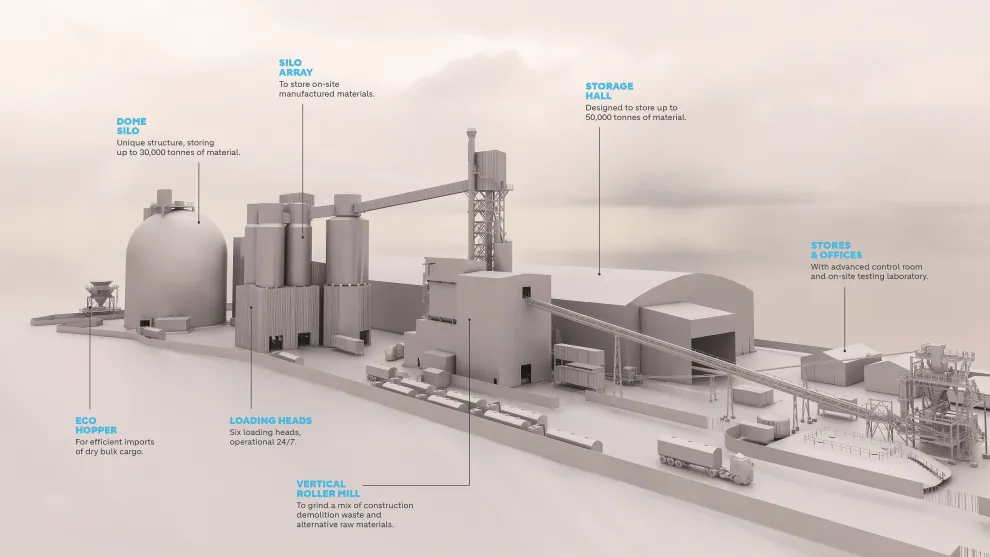

With a storage hall and dome silo that can hold 50,000 tons and 30,000 tons of cementitious materials, Tilbury will significantly expand Holcim UK’s cement production capacity, enhancing our ability to serve customers across Southern England and beyond with an unparalleled, future-ready product range – 24/7.

Once fully operational at the start of 2027, this advanced facility – with unique infrastructure that allows for high-precision, bespoke material blending for advanced formulations – will manufacture and supply a diverse range of traditional and innovative products, including ECOPlanet cement with ECOCycle inside, and other low-carbon and circular cementitious materials. Tilbury will become the UK’s primary hub for our ECOCycle technology, enabling the facility to mine and process construction demolition materials (CDM) to build cities from cities.

Tilbury will also be a highly integrated, "smart" cement plant that leverages real-time data and predictive maintenance to streamline the entire process from production to invoicing. By combining innovative storage solutions with an on-site blending facility, the site will deliver a wide range of bespoke materials with superior quality and efficiency. Its strategic deep-sea port location will facilitate global imports via large freight vessels, with automated loading systems and a 100% electric vehicle fleet ensuring faster turnaround times and a significantly reduced environmental footprint.

A circular landmark

Every element of the terminal’s development has been shaped by circular principles and carbon-conscious choices. Over 25,000 m3 of concrete from the original site has been recycled and reused, alongside 10,000 tons of recycled asphalt plannings incorporated into new surfacing solutions. Nearly 20,000 tons of excavated material has been recycled through our waste management business.

During construction, we’ve used a broad range of lower carbon materials from our own portfolio - including ECOPact ready-mix concrete, precast components, recycled aggregates, and reclaimed asphalt - ensuring our sustainability ambitions will be reflected not just in the products we deliver, but in the way we’ve built the site itself.

Engineering innovation

At the heart of the facility is the Vertical Roller Mill (VRM) designed to pioneer the processing of alternative raw materials and construction demolition materials (CDM). This enables the site to serve as a grinding and blending hub for:

- ECOPlanet cement: offering 30% lower embodied CO2 than standard Portland cement.

- GGBS (Ground Granulated Blast Furnace Slag): a low-carbon byproduct of steel manufacturing, an innovative formulation that can be used to directly replace Portland cement and reduce embodied CO2 in cementitious materials.

- ECOPlanet with ECOCycle cement: As part of our commitment to drive circular construction across the UK, we will introduce ECOPlanet with ECOCycle technology - an independently verified cement made with recycled CDM.

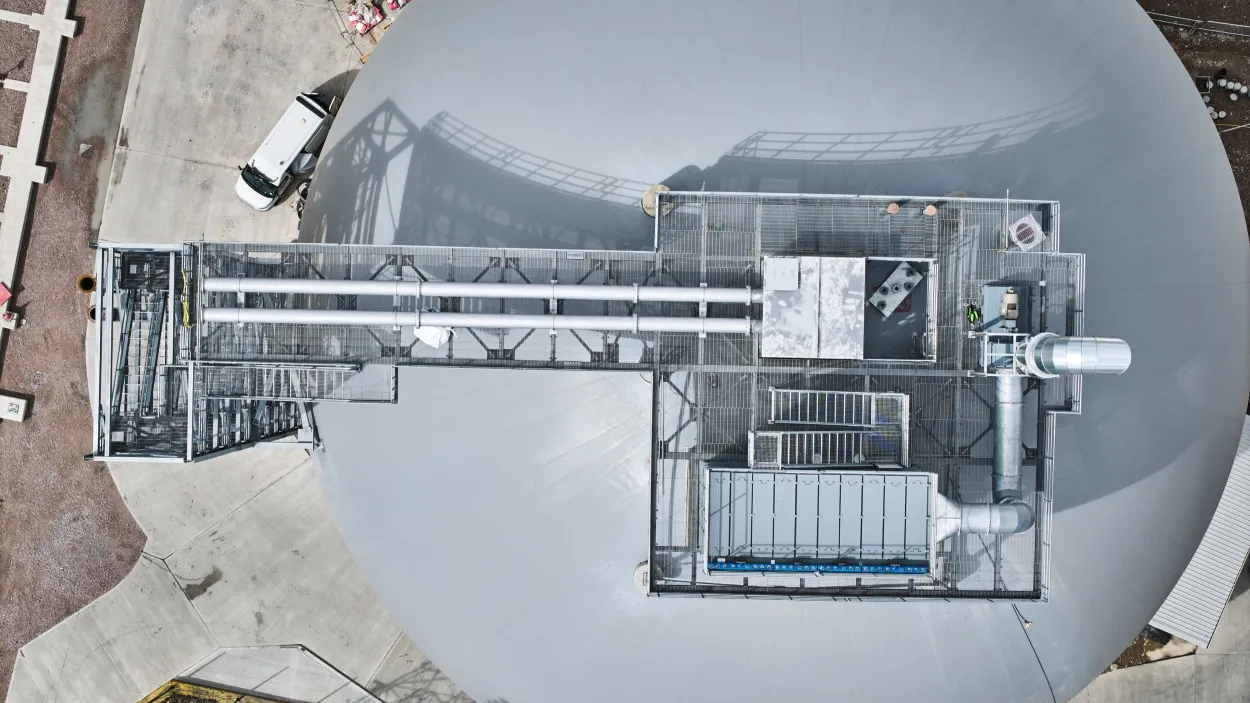

The striking and state-of-the-art 30,000-ton capacity dome silo, standing 45 meters high, maximizes storage volume while minimizing the physical footprint – a necessity in the high-density environment of the Port of Tilbury.

Tilbury is built around one clear promise, which is making sustainable construction a reality. The systems being installed at our Tilbury Cement Works are not only investments in innovative equipment and infrastructure, but a commitment to our sustainable innovation pipeline.

Strategic location

Tilbury’s location is highly strategic, and using the River Thames, Holcim can leverage water-bound freight, significantly reducing the number of heavy goods vehicles (HGVs) on the road, resulting in fewer lorry miles to deliver materials wherever they’re needed.

With six high-capacity loading points and five weighbridges, the terminal will operate 24/7, providing the agility required to serve major infrastructure projects in London and the South East, and meet the UK’s rising demand for high-performance, sustainable materials.

An eco-hopper on the quay enables efficient, dust-free discharge of dry bulk cargo directly from Holcim’s shipping fleet, maintaining air quality and operational efficiency.

The facility also includes a state-of-the-art laboratory and centralized control room, ensuring that every batch of low-carbon cement meets rigorous British standards.

For more information, visit www.holcim.co.uk/tilbury