Circularity first: A second wind for turbine blades

As the winds of change blow across Europe, wind power continues to soar in popularity. However, a new challenge has emerged: “What to do with wind turbine blades at the end of their lives?”

With the BLADES2BUILD partnership, an EU‑funded project bringing together 14 corporate and academic partners from eight countries, Holcim is making great strides to provide a scalable solution whereby we transform old blades into sustainable building solutions such as ECOPact low-carbon concrete and close the loop.

Sustainability driving profitable growth is a key driver of our strategy NextGen Growth 2030. We’re scaling circular construction worldwide and partnering to accelerate sustainable construction through collaborations such as BLADES2BUILD.

By 2030, the European onshore and offshore wind market is expected to grow by 40%. While this is good news for clean energy, it’s also expected to generate millions of tons of composite waste.

Wind turbines reach the end of their service life after 25-30 years of operation. While many components are recyclable, the blades—made of composite materials—have traditionally ended up in landfill. Here’s how BLADES2BUILD is working to ensure circularity instead.

Europe’s first circular wind farm

In a landmark step toward solving the blade waste challenge, multinational power company Endesa and Holcim have successfully demonstrated a full-scale circular solution at the Aldeavieja wind farm in Ávila, Spain.

As part of the facility’s repowering project, 22 aging turbines were dismantled and replaced by four modern ones, increasing capacity from 14.5 MW to 24 MW. Instead of discarding the old blades, the team reused them, incorporating recycled fibers from the blades into ECOPact concrete for the site’s new turbine foundations using Holcim’s circular technology, ECOCycle®.

This marks the first time in Europe that decommissioned wind blades have been used in new wind farm infrastructure.

“Aldeavieja is now the first wind farm in Europe to complete its own lifecycle by using structural waste for repowering,” says Pilar Lara, Project Manager in charge of Engineering and Construction Projects at Endesa.

From blade to building material: How it works

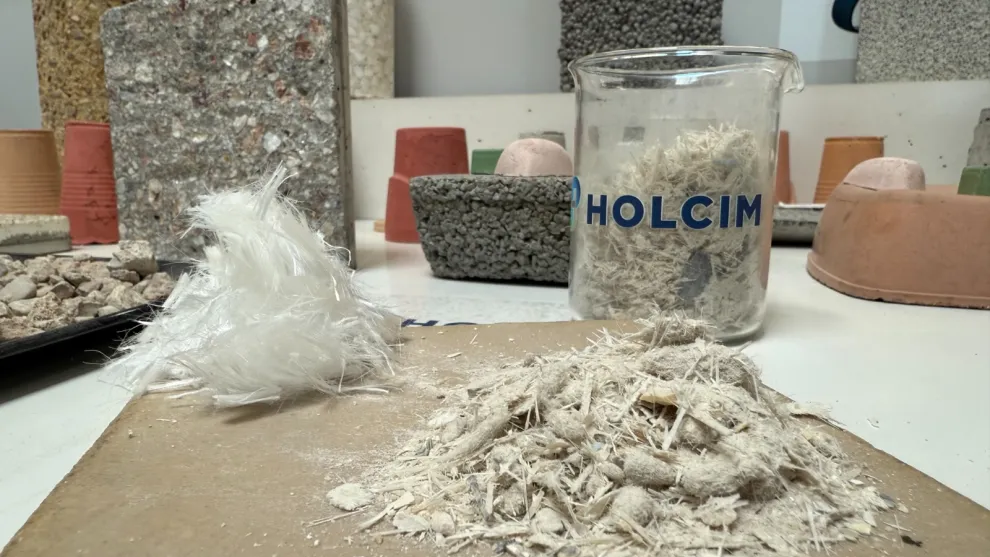

The recycling journey begins when the old turbine blades are cut into transportable sections and delivered to a crushing facility. There, the composite material is milled into an alternative aggregate, used as a partial replacement for natural aggregates in the concrete.

Holcim Innovation Center in Lyon and Holcim Spain’s concrete lab in Madrid developed this unique formulation, ensuring the concrete would maintain its workability and durability in line with industry standards.

Blades2Build: European public funding in action

BLADES2BUILD aims to develop scalable, real-world solutions for the circular reuse of wind turbine blades, one of the most technically challenging components in renewable energy end-of-life management. Aldeavieja wind farm is BLADES2BUILD’s first project.

“As part of Holcim’s NextGen Growth strategy, we aim to recycle more than 20 million tons of construction demolition materials by 2030. BLADES2BUILD will contribute to that ambitious target, not only for concrete but also for other applications.”

Scaling up circularity

Beyond proving the technical and economic viability of this solution for the treatment of wind turbine blades, BLADES2BUILD will prove its scalability with a 6,000 m² treatment plant currently under construction in Castilla y Leon. The region has the highest installed wind power capacity in Spain, representing 23% of the national total.

As the first project, Aldeavieja is more than a standalone proof-of-concept: it’s a scalable prototype for the future of renewable energy infrastructure, and a testimony to the power of cross-sector collaboration in accelerating sustainable construction.