Carbon Capture, Utilization and Storage

At Holcim we are decarbonizing construction for a net zero future. This starts with our operations, and we focus on three levers: formulation, energy and advanced technologies including carbon capture utilization and storage (CCUS).

We have identified over 20 flagship CCUS projects based on mature technologies, as well as robust partnerships and value chains. Of these, eight full-scale projects in Europe have been awarded grants by the European Union Innovation Fund and aim to go live by 2030.

With these projects in execution, we have committed to invest CHF 2 billion gross CAPEX in CCUS, to produce 8 million tons of near-zero cement and capture around 5 million tons of CO2 annually by 2030.

These projects are practical, scalable and supported by cutting-edge technology – positioning Holcim at the forefront of the global shift towards decarbonization and enabling us to offer our customers the most sustainable building solutions.

To effectively capture, transport, store and use CO2, Holcim is establishing robust partnerships with industry experts across the carbon management value chain. We are creating a new CO2 value chain that helps to achieve climate goals and generates financial returns.

Holcim is on course to make near-zero cement and concrete a reality at scale this decade – thanks to the strength of our engineering teams, our mature technologies and partnerships that span the value chain.

Reaching net zero with ccus

We are scoping CCUS and mineralization projects around the world and our diverse portfolio ranges from CO2 storage to CO2 utilization. Based on mature technologies and robust partnerships and value chains, our flagship projects are well positioned to become near-zero cement plants and produce near-zero cement. We have further projects in early-stage development to make CCUS a reality at scale across key markets worldwide.

Driving decarbonization in Europe

Holcim has been selected for grants from the European Union (EU) Innovation Fund for carbon capture projects in Belgium, Croatia, Greece, Germany, Poland and Romania, as well as two in France. These eight projects are based on highly scalable, mature technologies and advanced partnerships, putting clean technologies to work for Europe’s net-zero future.

Our CCUS Pathways

1. Mineralization

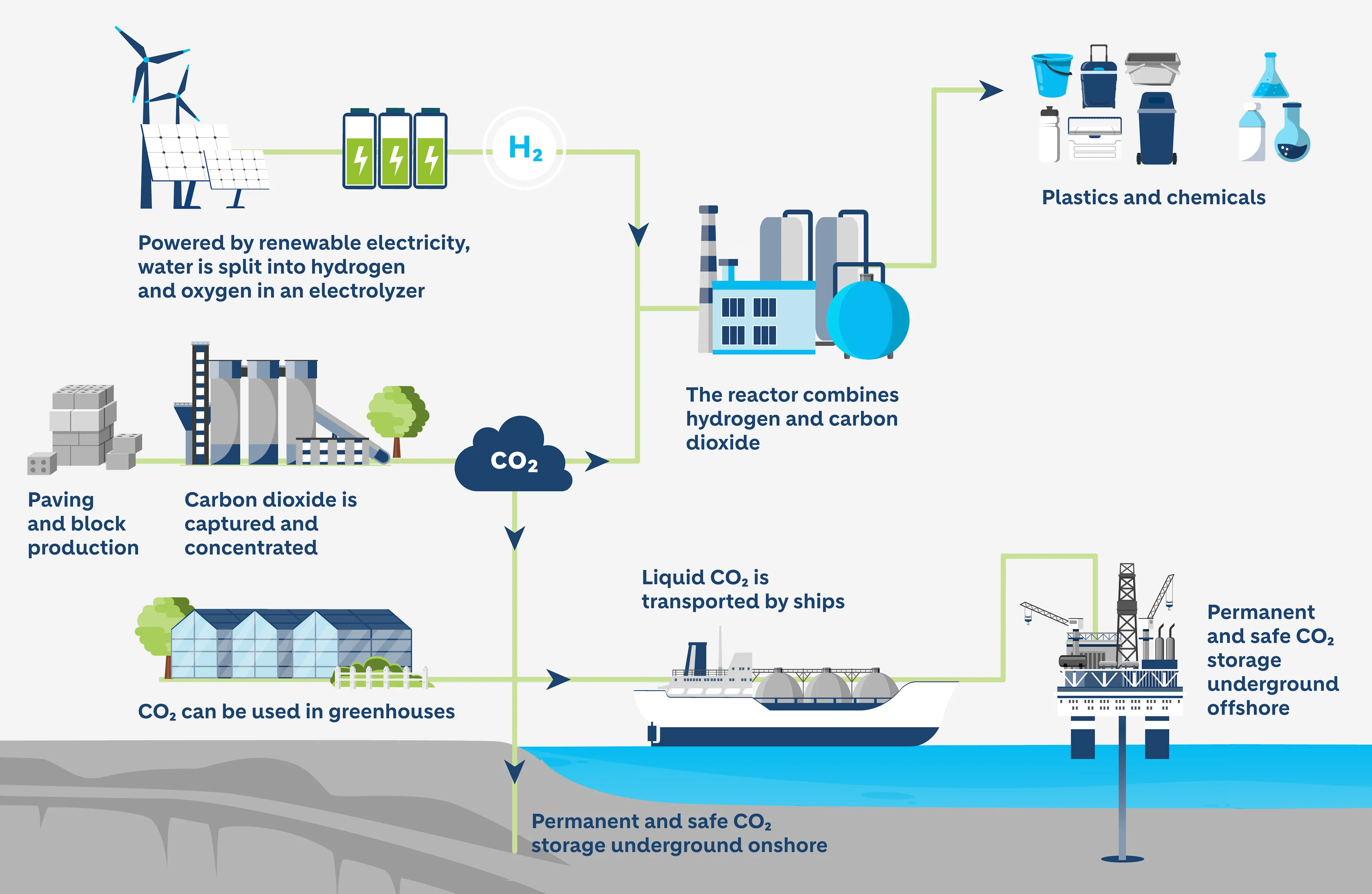

CO2 is reacted with minerals to form carbonates, storing the CO2. In the cement sector, this reaction then enables CO2 capture for use as a raw material to produce new building materials.

2. Conversion utilization

CO2 can be repurposed by reaction with low-carbon hydrogen to produce chemicals and plastics or decarbonize the aviation and maritime sectors through the production of sustainable fuels.

3. Market utilization

Captured CO2 can be used for greenhouse plants as a crop growth enhancer or for beverage carbonation, for example.

4. Storage

After CO2 is captured from a facility, it is transported – via pipeline, train, ship or truck – and safely stored underground either onshore or offshore.

scalING up CCUS

There is no “one-size-fits-all” CCUS solution. To optimally deploy CCUS, these projects should be executed in combination with suitable advanced technologies that modernize the cement plant; enhancing efficiency and significantly improving the CO2 profile of the plant before installing the capture plant. Moreover, different sites have different available storage or utilization options, and regulations may vary between countries.

Holcim is tailoring pathways and value chains based on the local conditions. Working with other private companies as well as with start-ups, we have a portfolio of diverse and cost-effective CCUS solutions that can be scaled across the company.

Deep collaboration among public authorities, private companies, local stakeholders and other value chain partners is essential to securing the development of technologies that will unlock the business case for CCUS and enable a net-zero future.

Holcim is currently piloting the broadest range of CCUS technologies – from capture and CO2 treatment to transportation and storage – to bring these technologies to market at scale in a competitive way.

Frequently asked questions

Talk to an expert

Want to learn more about our CCUS projects? Drop us a line, and someone from our team will be in touch.